Zirconia (ZrO2) – CeramaZirc™

Dubbed ‘ceramic steel’, Zirconia (Zro2) ceramic offers a combination of high hardness, wear and corrosion resistance, while exhibiting one of the highest fracture toughness values among all ceramic materials.

There are several grades of Zirconia available –, the most common of which are Yttria Partially Stabilized Zirconia (Y-PSZ) and Magnesia Partially Stabilized Zirconia (Mg-PSZ). Both of these materials offer excellent properties. However, the operating environment and design will dictate which grade may be suitable for specific applications. Its high thermal expansion and unique resistance to crack propagation make it an excellent material for joining with metals like steel.

上一页

下一页

Material Advantages

- Use temperatures up to 1000°C

- Low thermal conductivity

- Chemical inertness

- Resistance to molten metals

- Wear resistance

- High fracture toughness

- High hardness

Applications

- High pressure equipment ball valve balls and seats

- High density ball grinding media

- Rollers and guides for metal forming

- Thread and wire guides

- Metal extrusion dies

- Deep well down-hole valves and seats

- Powder compacting dies

- Pump seals and shaft bearings

- Oxygen sensors

- High temperature induction furnace susceptors

- Fuel cell membranes

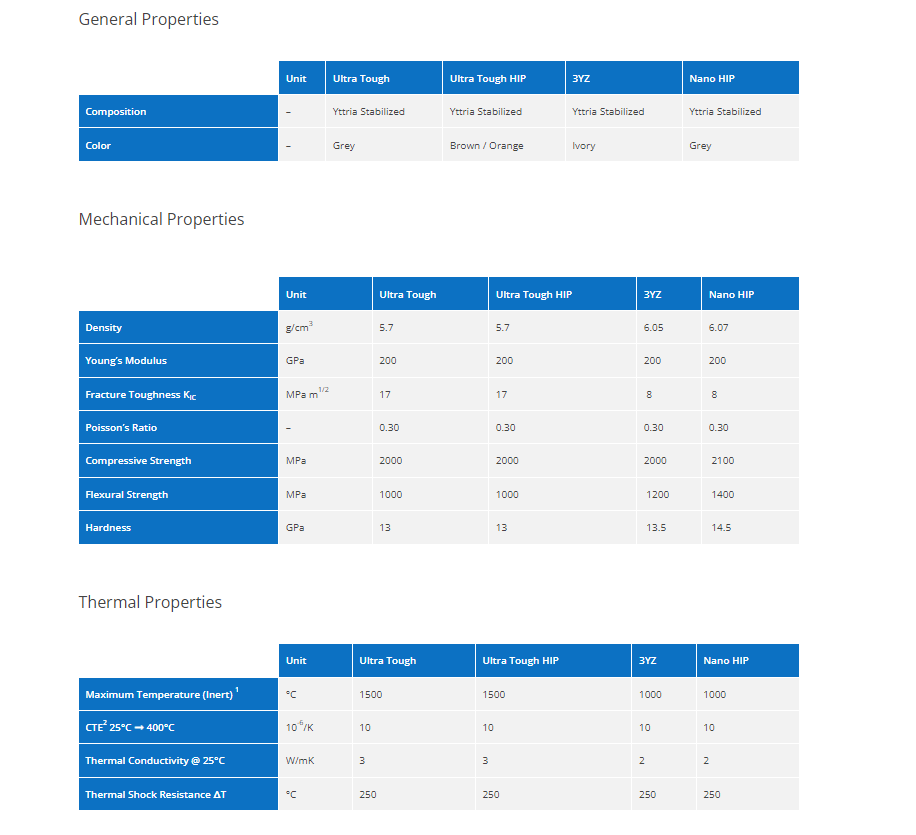

Material Properties