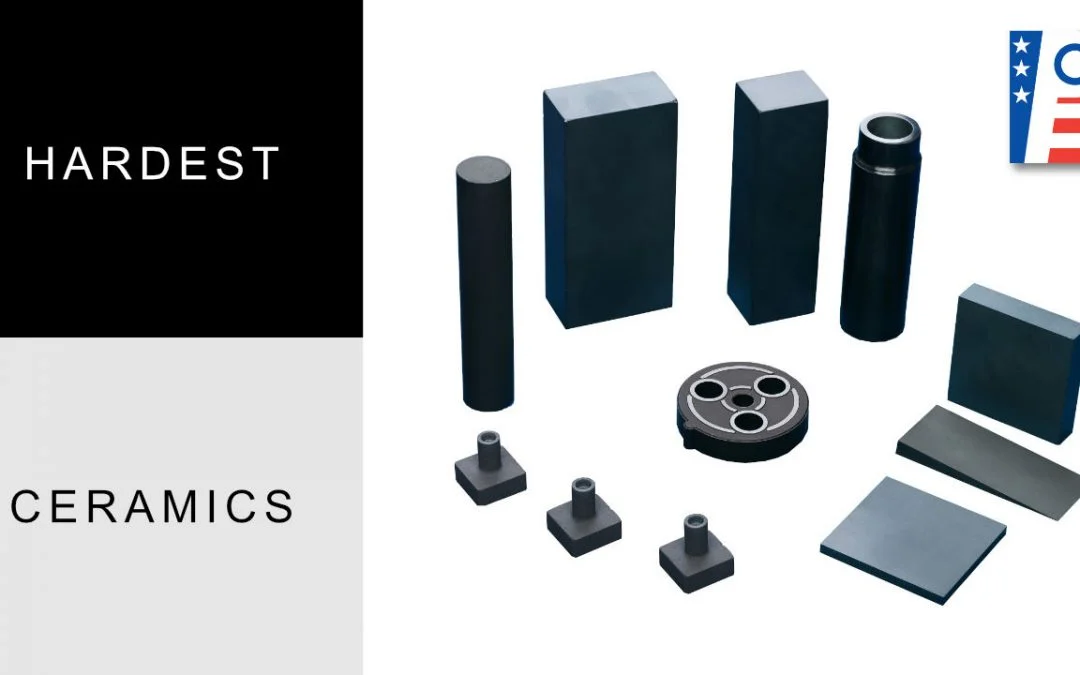

In the world of technical ceramics, there are two materials that are surpassed only by diamond and cubic boron nitride in terms of hardness – and both are used by Precision Ceramics USA as a base material for a wide range of technical components in an equally wide field of applications.

Boron Carbide (B4C) is currently the hardest material produced in tonnage quantities and is the third hardest material known to man after diamond and cubic boron nitride. Not far behind it in the hardness stakes comes silicon carbide (SiC), steeped in history since it was first mass-produced in 1893 and probably the most common of all industrial abrasives.

B4C

The extreme hardness of boron carbide provides excellent wear and abrasion resistance and,

consequently, it is a perfect base material for the manufacture of nozzles for slurry pumping, grit

blasting, and water jet cutters.

In combination with other materials, boron carbide also finds extensive use in ballistic armor (including body and personnel armor), where its combination of high hardness, high elastic modulus, and low density gives the material exceptionally high specific stopping power to defeat high velocity projectiles.

Other applications include ceramic tooling dies, precision tool parts, jigs, and other high wear

applications.

SiC

The technical properties of silicon carbide are remarkably similar to those of diamond. It is one of the lightest, hardest, and strongest technical ceramic materials and has exceptional thermal conductivity, chemical resistance, and low thermal expansion.

Silicon carbide is an excellent material to use when physical wear is an important consideration, because it provides good erosion and abrasive resistance, making it particularly suitable for such applications as spray nozzles, shot blast nozzles, and cyclone components.

Not so long ago, silicon carbide was the chosen material to line the brakes of the most advanced, jaw-dropping cars the world has ever seen; the McLaren P1 for example.